What is CNC?

An acronym for Computerized Numerical Control, CNC is a computerized manufacturing process in which the movement of production equipment is regulated by pre-programmed software and code controls the movement of production equipment. It is used to control the movement of a wide range of complex machinery, including turning mills, lathes, and grinders—all of which are used to cut, shape, and create different parts and prototypes.

What is a CNC Machine?

As opposed to “old school” devices that were manually controlled by hand wheels or levers, CNC machines are operated by computers executing a pre-programmed sequence of controlled commands. These fully automated machines understand the specialized CNC machining language called G-code, which relays the precise measurements for production, including feed rate, speed, location, and coordination. Because the parts’ mechanical dimensions are defined using computer-aided design (CAD) software, and then translated into manufacturing directives by computer-aided manufacturing (CAM) software, having knowledgeable CNC machinists, operators, and programmers involved in the process is key.

The Importance of CNC Machining

CNC machining is not the typical manufacturing job. It is an innovative, meaningful career path that allows creative people to see a product through each phase of its creation, from the start of an initial concept to design, to code, and then to the finished product.

What is it like to be a CNC Machinist?

After appropriate training, CNC machinists and operators handle a wide variety of tasks such as:

- Reading blueprints, sketches, Computer-Aided Design (CAD) files, and Computer-Aided Manufacturing documents.

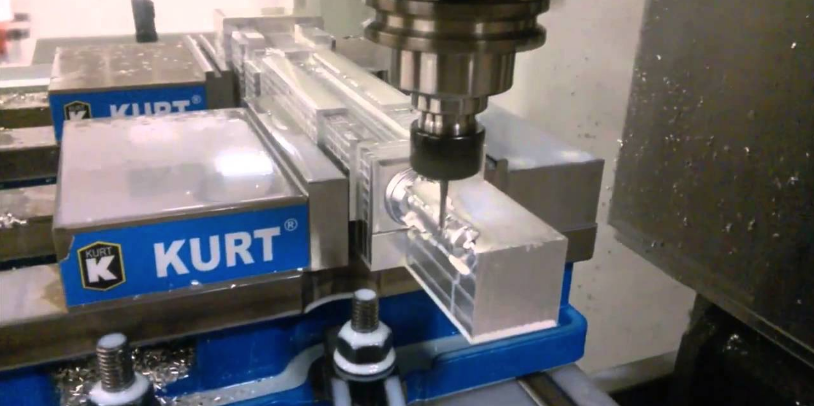

- Assembling, operating, and taking apart manual, automatic, and computer numerically controlled (CNC) machine tools.

- Aligning, securing, and adjusting cutting tools and workpieces.

- Monitoring the speed and feed of machines.

- Turning, milling, drilling, shaping, and grinding machine parts to specifications.

- Measuring, examining, and testing completed products for defects.

- Smoothing the surfaces of parts or products.

- Presenting finished workpieces to customers, modifying as needed.

For people who are creative, detail-oriented, and enjoy working with their hands, a certificate or degree in CNC technology from a reputable manufacturing school is a great investment in the future. A program that gives students a thorough understanding of manufacturing mathematics, processes, and materials is a good start. Gaining competence in technical drawings, specifications, and computer-aided machining, along with practical experience in leading-edge CNC technologies, will take the aspiring machinist even further.

What Makes a Good CNC Machining Program?

Look for programs that teach students on CNC 3-axis milling and turning machines. Ask if the program includes instruction on the advanced Mastercam skills needed to program tool location, motion, feed, and speed. When a student successfully finishes a CNC Machinist program, they are ready to take the National Institute for Metalworking Skills (NIMS) test to earn the credentials needed to become a CNC operator.

According to the US Bureau of Labor Statistics, overall employment of machinists and tool and die makers is projected to grow 3 percent from 2019 to 2029, about as fast as the average for all occupations. Many job opportunities are expected to arise from the need to replace workers who leave the occupation each year.