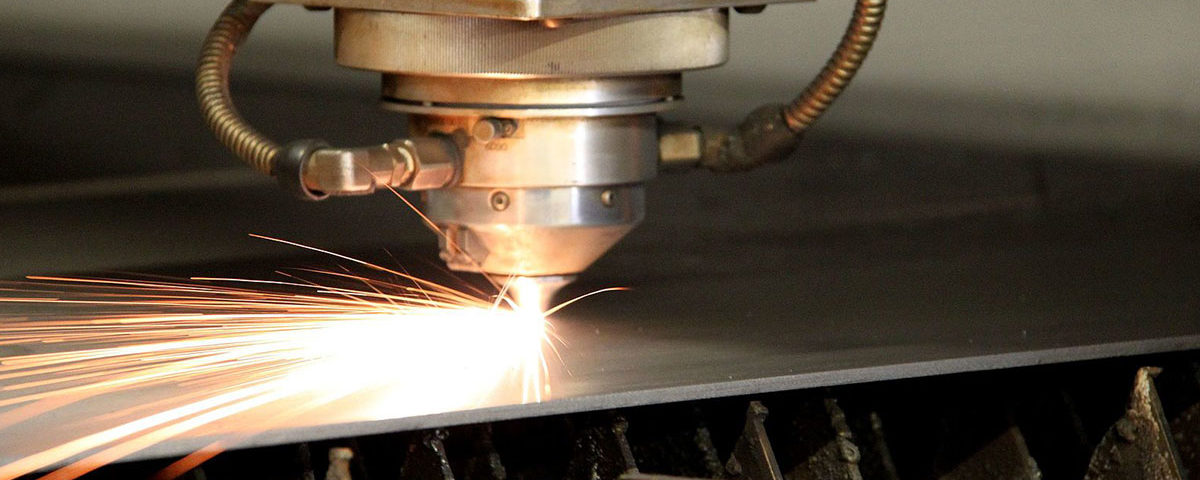

When it comes to cutting in the fabrication of sheet metal, you do have options… but we believe the laser cutting technique should be your hands-down choice.

Why?

Laser cutting is the fastest and most accurate cutting technique—especially for sheet metal fabrication. There is a cost, however, associated with this level of speed and precision. Purchasing a laser cutting machine is a significant investment—which is why this piece of equipment is almost exclusively found in progressive manufacturing environments.

Lasers deliver outstanding quality and accuracy, with the flexibility to cut material into almost any conceivable shape with the highest level of detail. We believe there are four reasons to choose laser cutting as your preferred method of fabricating sheet metal:

Here are 4 major reasons to choose laser cutting over other techniques for fabricating sheet metal.

Sleek Cut Edges

Using the laser cutting technique, the beam that is directed onto the sheet metals is completely focused on one specific spot, generating far less heat to the material. This means the laser’s path gets narrowed down, producing the cleanest cut edges. This small HAZ (Heat Affected Zone), combined with the machine’s small kerf, allows it to cut intricate, highly detailed shapes including holes and lines. This level of speed and precision is a main reason the laser technique should be your preferred method of cutting in sheet metal fabrication.

Minimal Warping

There is always a chance of warping during the metal cutting process, but using the laser cutting technique significantly reduces that. The processing speed, combined with the laser’s HAZ, reduces the odds of sheet metal warping or becoming distorted.

Unlimited Customization

The ability to fabricate sheet metal to your client’s exact specifications adds to your company’s value proposition and customer appeal. Laser cutting allows you to cut material quickly and accurately without regard for the thickness of the sheet metal or the intricacy of the shape required. Using the laser cutting method allows you to deliver the sheet metal job precisely to your customers’ specifications every time.

Speed and Efficiency

Depending on metal type, tolerances, material thickness, and intricacy of the specifications, the speed of the laser can be as fast as 20-70 inches per minute. Although loading in the sheet metal and programming the laser cutter takes time and expertise, setup is simplified when the laser cutter is equipped with dual tables that automatically calibrate and position themselves as needed. Modern lasers ensure that the sheet metal is placed straight and that the machine is programmed to recalculate the position of the shape being fabricated accordingly while continuing to optimize available space.

At EDCO, we highly recommend choosing the laser cutting technique in sheet metal fabrication. Contact us today to see how we can help you!