A key user of Precision Sheet Metal Fabrication is the military, but the telecommunications, computers, medical, electronics, automobile, food services, and construction industries also rely on it to optimize their sheet metal during the product manufacturing production phase.

Adapting Precision Sheet Metal Fabrication provides both manufacturing companies and clients with three major benefits:

- Ensures an exact fit for all system components. Meeting a project’s requirements to the letter is one of the most important parts of ensuring its success. If a part isn’t precisely fabricated to the client’s specifications for where it’s being installed in the project, the entire system may not function properly. Precision Sheet Metal Fabrication helps ensure an exact fit for all components.

- The process is safer. When the component parts are well-designed, carefully measured, and appropriately fabricated, the overall manufacturing process is safer. Precision Sheet Metal Fabrication helps uphold the highest standards of manufacturing, which inevitably lead to the best outcomes and results.

- Manages production of replacement parts more efficiently. The ability to quickly, safely, and precisely manufacture replacement parts for any system is an important part of keeping it up and running with minimal down time. Precision Sheet Metal Fabrication delivers an attention to detail that is key to maintaining your systems’ production and delivery schedule.

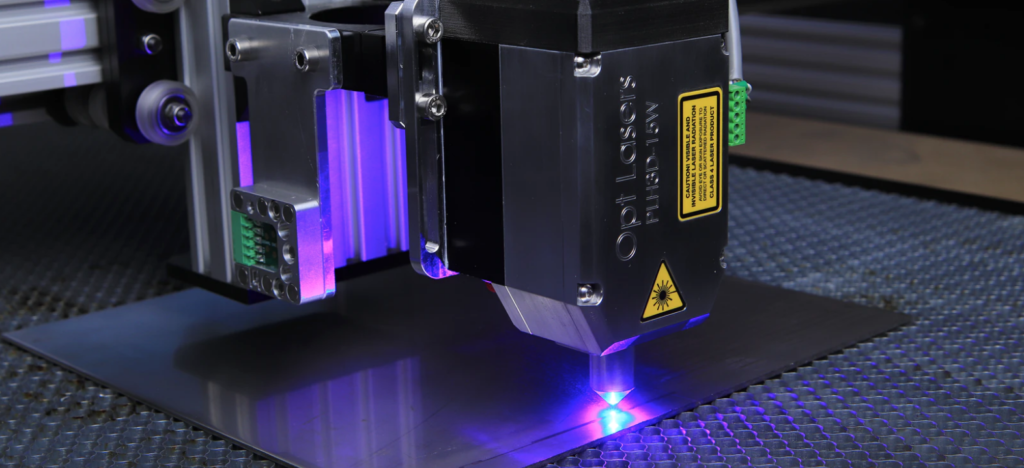

To ensure that each piece of sheet metal is properly used, and as little material as possible is wasted during the production process, manufacturing companies rely on specialized computers and sophisticated software programs like CAD/CAM. Manufacturers use press forming, bending, roll forming, and annealing to create complex designs to ensure the precise fabrication of all parts, efficiently, exactly and right on spec. To remove excess material, this process may also include additional steps such as sawing, stamping, shearing, and drilling.

Most of these parts are then optimized using Computer Numerically Controlled (CNC) machines. These machines make handling tasks related to customized specifications easier and more exact than ever before.

EDCO has invested fully in Precision Sheet Metal Fabrication because we believe it is the most reliable way to make sure our manufacturing process is precise, efficient, safe, secure, and completely in line with the highest modern standards. These are the true benefits of precision sheet metal fabrication.